Nano plastics have become a recent topic of concern within society. However, there is a knowledge gap on nano plastics related to their concentration in the environment and the harmful effects they pose to ecosystems and living organisms. In addition, there is currently no way of detecting or removing nano plastics from the environment. During my graduation internship I worked on the topic of producing these nano plastics. If you are thinking ‘why are you making them? You are just polluting more’, let me explain.

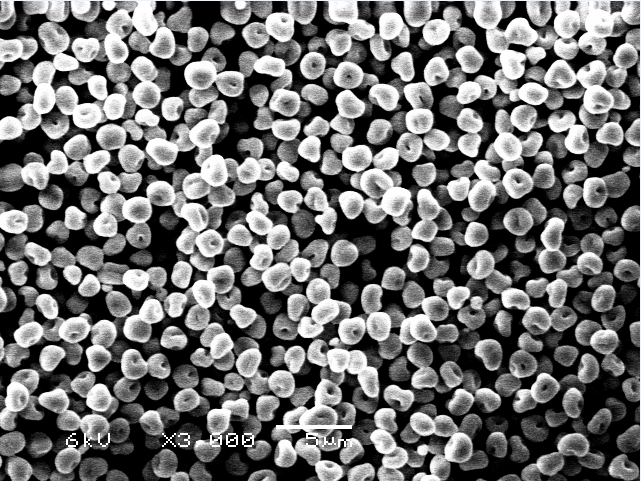

To develop techniques and methods for nano plastics detection and removal, it is essential to understand their behavior and the pathways they follow. Therefore, the aim was to produce nano plastics doped with a metal. This metal would act as a tracer, and thus the produced particles could be used for the development of tools that would detect and identify them in a water sample.

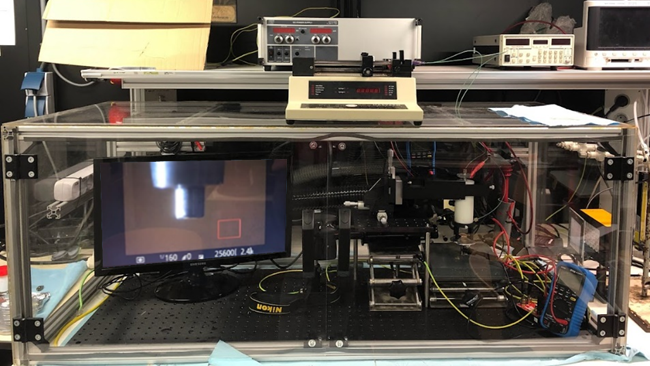

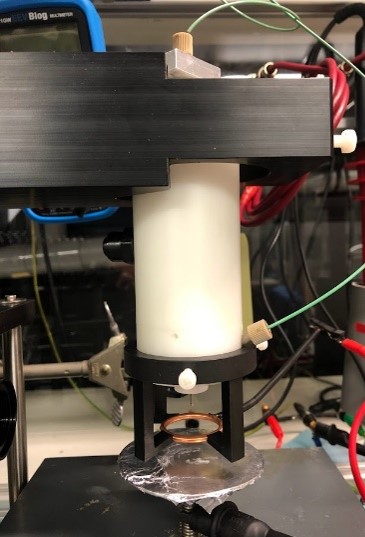

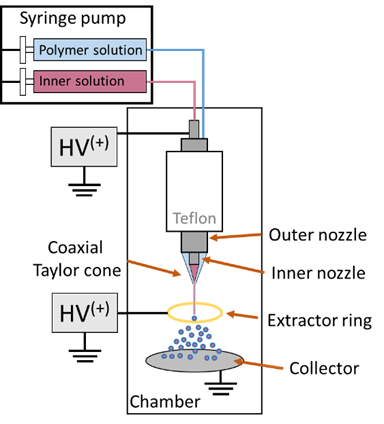

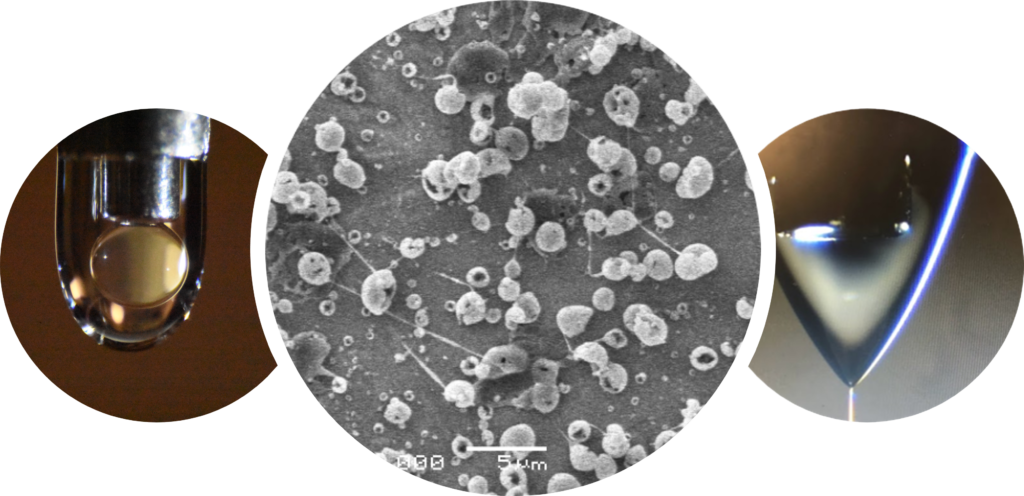

Now, how did we make these nano plastics? A technique called Electrohydrodynamic Atomization (EHDA) was used. This technique can be used for the production of stable nanoparticles and allows for the production of core-shell particles. Using this technique simply meant we could choose the physical (shape and size) and chemical (element) properties of the nano plastics. By knowing the initial form of the nano plastics, it could be possible to validate technologies such as field-flow fractionation (FFF). This technique provides elements and size information regarding nanoparticles present in a water sample.

Overall, there were multiple challenges and obstacles to overcome. Understanding a completely new technology like EDHA was not easy. However, we got one step closer to producing these particles and understanding how they behave. I was happy to be a small part of producing these nano plastics to eventually be able to remove these pollutants from the environment.